|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

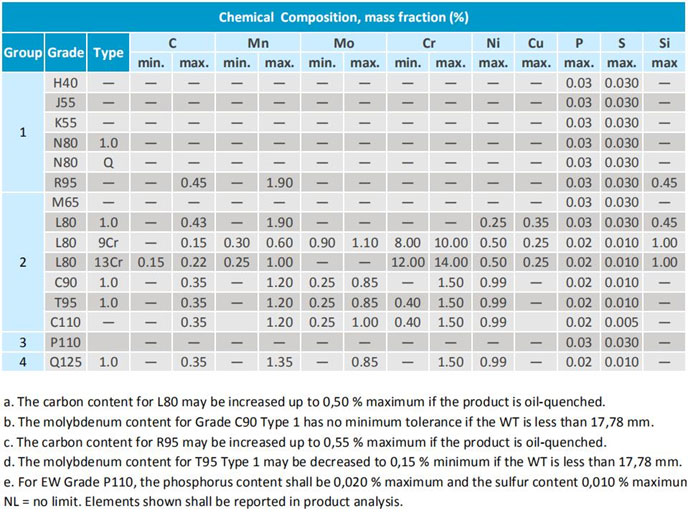

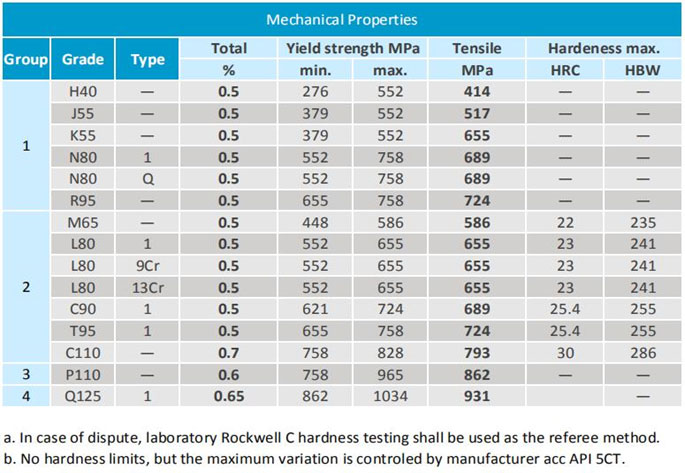

Steel Code / Steel Grade |

|

CASING AND TUBING |

API 5CT |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95, P110, Q-125

|

|

Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells |

SY/T 6194 / BS EN ISO 11960 / NF M87-207 |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

H-40, J55, K-55, N-80, N80Q, C-75, L-80, C-90, T-95, P110, Q-125 |

|

SEAMLESS STEEL OIL WELL CASING, TUBING AND DRILL PIPE

|

JIS G3439 |

Casing:OD 4 1/2"- 20" (114.3mm-508mm) Tubing:OD 2 3/8" - 4 1/2" (60.3mm-114.30mm) WT: 0. 205"- 0.635" |

STO-H, STO-J, STO-D, STO-E |

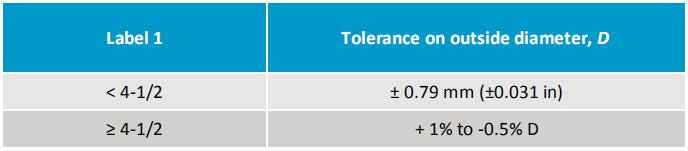

Below tolerances apply to the outside diameter, D, of casing and tubing:

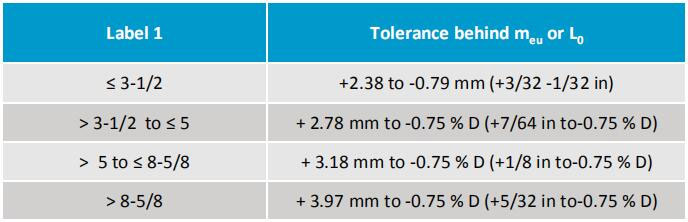

For upset integral tubing connection

Following tolerances apply to the outside diameter of the pipe body immediately behind the upset for a distance of approximately 127 mm (5.0 in) for sizes Label 1: 5-1/2 and smaller, and a distance approximately equal to the outside diameter for sizes larger than Label 1: 5-1/2. Measurements shall be made with callipers or snap gauges.

Wall thickness

Tolerance for casing and tubing wall thickness is -12.5%.