|

Type A |

Elements |

Heat Analysis, % |

|

1 |

Columbium |

0.005-0.05B |

|

2 |

Vanadium |

0.01-0.15C |

|

3 |

Columbium |

0.005-0.05B |

|

4 |

Vandadium |

0.01-0.15C |

|

5 |

Columbium plus vanadium |

0.02-0.15D |

|

6 |

Titanium |

0.006-0.04 |

|

7 |

Nitrogen |

0.003-0.015 |

|

8 |

Vanadium |

0.06 max |

Table 3: Alloy elements composition

A: Alloy content shall comply with Type 1, 2, 3, or 5 and shall be on test report.

B: Product analysis limits = 0.004 to 0.06%.

C: Product analysis limits = 0.005 to 0.17%.

D: Product analysis limits = 0.01 to 0.16%.

Mechanical Properties

|

Grade |

Yield Point, min |

Tensile Strenth, min |

Minimum Elongation, % B,C,D |

|||

|

kis |

[MPa] |

ksi |

[MPa] |

in 8 in[200 mm] |

in 2 in[200 mm] |

|

|

42 [290] |

42 |

[290] |

60 |

[415] |

20 |

24 |

|

50 [345] |

50 |

[345] |

65 |

[450] |

18 |

21 |

|

55 [380] |

55 |

[380] |

70 |

[485] |

17 |

20 |

|

60 [415] |

60 |

[415] |

75 |

[520] |

16 |

18 |

|

65 [450] |

65 |

[450] |

80 |

[550] |

15 |

17 |

A: Specimen shall comply with Specification of A6/A6M.

B: Elongation not required to be determined for floor plate.

C: For wide flange shapes over 426 lb/ft [634 kg/m], elongation in 2 in. [50 mm] of 19% minimum applies.

D: For plates wider than 24 in. [600 mm], the elongation requirement is reduced two percentage points for Grade 42, 50, and 55 [290,345,and 380], and three percentage points for Grade 60 and 65 [415 and 450]. See elongation requirement adjustment in the Tension Tests section of Specification A6/A6M.

General Requirements for Delivery

Structural steel plates furnished under ASTM A572 shall comply with requirements of the current edition of Specification A6/A6M, for the specific structural product ordered, unless a conflict exists in which case this specification shall prevail.

Coils are not applicable to this specification until they are processed to a finished structural product. Structural steel plates produced from coil means they have been cut to individual lengths from a coil. The processor directly controls, or is responsible for, the operations involved in the processing of a coil into a finished structural product. Such operations include decoiling, leveling or straightening, hot-forming or cold-forming (if applicable), cutting to length, testing, inspection, conditioning, heat treatment (if applicable), packing, marking, loading for shipment, and certification.

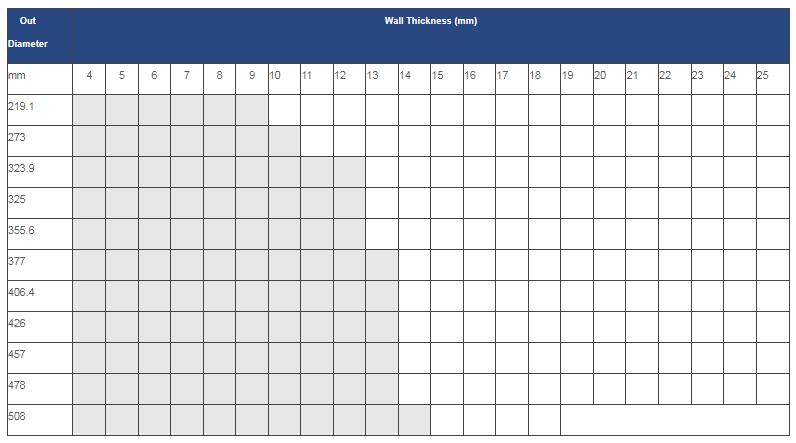

Our Supply Range:

Description: Carbon Steel ASME SA572/ ASTM A572 Grade C & D

Manufacturing Types: Hot Rolled

Thickness: 2 to 150 mm

Width: 0.6m to 3m

Length: 6m, 12m, customized

Surface: Natural, Painted

Packing: Standard sea packing, bundled with streel strip.

|

API 5L / ASTM A252/ EN10219-2/ ASTM A572 Spiral Steel Pipe |

API 5L / ASTM A252/ EN10219-2/ ASTM A572 SSAW Steel Pipe |

|

spiral welded pipe |

ssaw pipe |

|

welded tubes |

ssaw pipe supplier |

|

spiral welded steel pipe suppliers |

API 5L ssaw pipe suppliers |

|

spiral welded tube |

ASTM A252 ssaw pipe manufacturer |

|

pipa spiral welded |

API 5L gr.b ssaw pipe suppliers |

|

spiral seam pipe suppliers |

API 5L x42 ssaw pipe suppliers |

|

spiral steel tube |

API 5L x46 ssaw pipe suppliers |

|

spiral welded stainless steel pipe |

API 5L x52 ssaw pipe suppliers |

|

spiral seam welded pipe |

API 5L x60 ssaw pipe suppliers |

|

spiral seam pipe |

API 5L x65 ssaw pipe supplier |

|

spiral steel pipe |

API 5L x70 ssaw pipe supplier |

|

spiral pipe supplier |

ssaw pipe manufacturer |

|

spiral welded carbon steel pipe supplier |

Ssaw steel pipes |

|

spiral welded steel pipe supplier |

ssaw welding steel pipes |

|

spiral welded pipes manufacturer |

spiral pipe suppliers |

|

spiral welded pipe suppliers |

ssaw pipe in China |

|

Standard |

Standard |

|||||

|

SY/T5040-2000 |

Y/T5037-2000 |

SY/T9711.1-197 |

ASTM A252 |

AWWA C200-9 |

API 5L PSL1 |

|

|

Tube end OD deviation |

± 0.5%D |

± 0.5%D |

-0.79mm~+2.38 |

<± 0.1%T |

<± 0.1%T |

± 1.6mm |

|

Wall thickness |

± 10.0%T |

D<508mm, ±12.5%T |

- 8%T~+19.5%T |

<- 12.5%T |

-8%T~+19.5%T |

5.0mm |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5m |

|||||