Round Billet → Material Inspection → Grinding → Cut to Length → Heating → Piercing → Bite mandrel → Hot Rolled → Get Rid of Mandrel → Heat Treatmen t → Size Reducing → Cooling → Straightening → Semi Manufactured Product → Corp End Cutting off → UT/ET TEST or Hydrostatic Test → Marking → Packing → Warehousing

|

ASTM /ASME |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic and Austentic Alloy Steel Boiler, Superheater and Heat-Exchanger Tubes |

ASTM A213 |

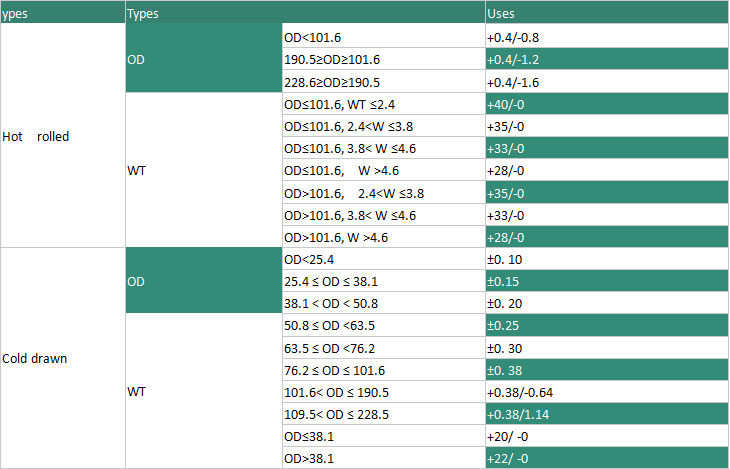

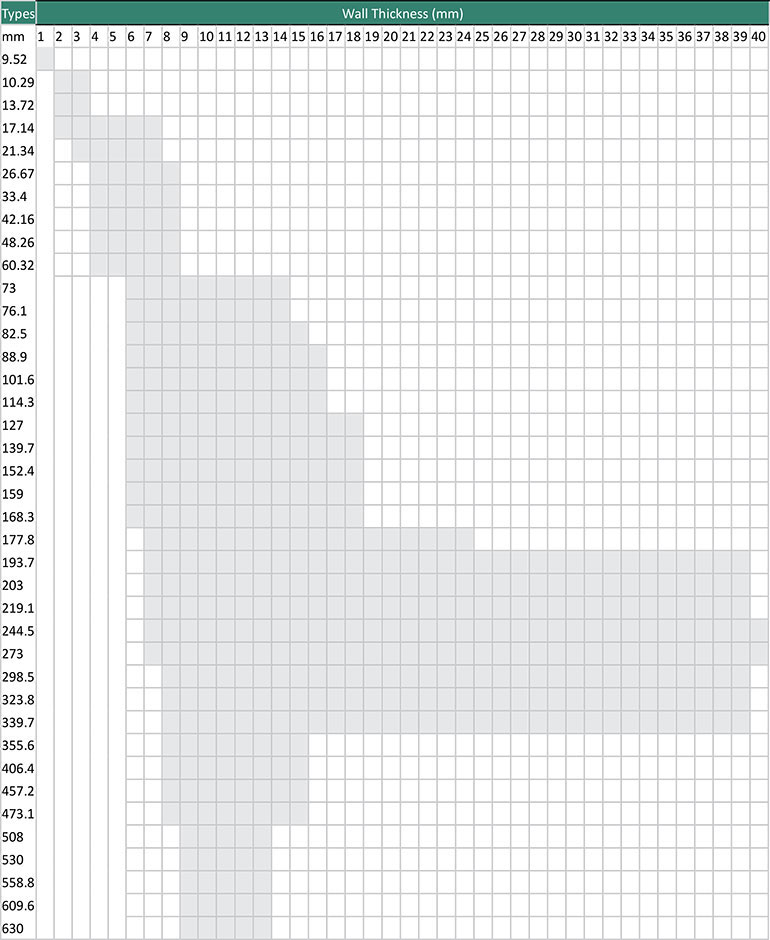

Ø9.52~630 x WT0.59~40 |

T2, T5, T9, T11, T12, T22, T91, T92 |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

ASTM A335 |

Ø10.3~1200 x WT2~200mm |

P5, P9, P11, P12, P22, P91, P92 |

|

Seamless Carbon and Alloy Steel for Mechanical Tubing |

ASTM A519 |

Ø10.3~323.9 x WT1.65~40mm |

4130, 4130X, 4140, 4145 |

|

EN |

|||

|

Product Name |

Executive Standard |

Dimension (mm) |

Steel Code / Steel Grade |

|

Seamless Ferritic Alloy Steel Pipes for High Temperature Use |

EN10216-2 |

Ø10.3~323.9 x WT1.65~40mm |

13CrMo4-5, 1-CrMo9-10, X10CrMoVNb9-1, 15NiCuMoNb5-6-4 |

Alloy steel seamless pipe is ideally suitable for chemical, petrochemicals and other energy-related applications. It has characteristics of high corrosion resistance and can be used in a wide range of industrial sectors.

- Chemical industries

- Petrochemical industries

- Energy-related applications

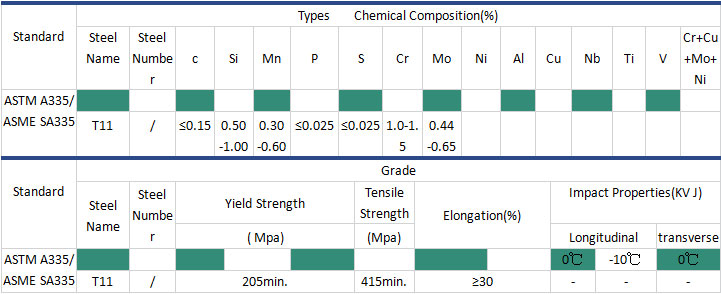

Chemical Composition and Mechanical Properties of ASME SA335 P11 Steel tube / ASTM A335 P11 Alloy Steel Seamless tubes :