|

GB |

ASTM/ASME |

JIS |

DIN |

EN |

|

GB/T14975-2002 |

A213/A213M |

G3446 G3447 |

DIN2462 |

EN10216-5 |

|

GB/T14976-2002 |

A249/A249M |

G3448 G3459 |

DIN2463 |

EN10217-7 |

|

GB13296-2007 |

A790/A790M |

G3463 G3468 |

DIN17457 |

|

|

GB/T12771-2008 |

A269 A358 |

|

DIN17458 |

|

|

GB/T12770-2000 |

A511 A688 |

|

|

|

|

GB/T19228.2 |

A778 A789 |

|

|

|

|

HG20537.2-92 |

A790 |

|

|

|

|

HG20537.3-92 |

B163 B167 |

|

|

|

|

HG20537.4-92 |

B338 B407 |

|

|

|

|

SH3501-2002 |

B423 B444 |

|

|

|

|

|

B622 B668 |

|

|

|

|

|

B677 B829 |

|

|

|

|

Austenitic |

Duplex |

Nickel Stainless |

Ti |

Ferrite |

|

304/L/H |

S31500 |

600625 |

Grade1 |

409L |

|

310S/H |

S32101 |

800825 |

Grade2 |

439 |

|

316/L/H |

S32003 |

400 |

Grade3 |

|

|

317/L |

S32304 |

N06985 |

|

|

|

321/H |

S31803 |

N10276 |

|

|

|

347/H |

S32205 |

|

|

|

|

S30432 |

S32750 |

|

|

|

|

S31042 |

S32760 |

|

|

|

|

904L |

|

|

|

|

|

6Mo(S79054) |

|

|

|

|

1. Petrochemical industry;

2. Electric industry;

3. The shipbuilding industry;

4. Low-pressure heater;

5. Offshore Oil platform;

6. Nuclear Power industry

7. The Oil and Gas industry;

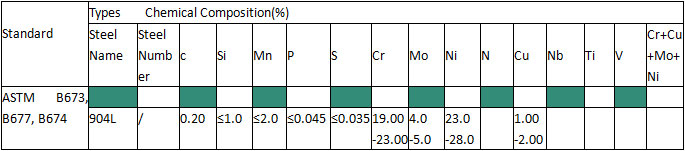

Chemical Composition of ASTM B673, B677, B674 904L Steel tube / ASTM B673, B677, B674 904L Stainless Steel tubes:

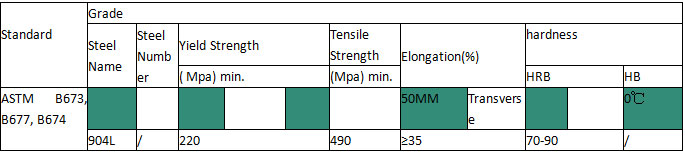

Mechanical Properties of ASTM B673, B677, B674 904L Steel tube / ASTM B673, B677, B674 904L Stainless Steel tubes:

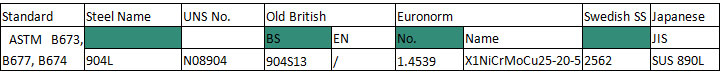

Grade Specifications of ASTM B673, B677, B674 904L Steel tube / ASTM B673, B677, B674 904L Stainless Steel tubes:

|

Wall Thickness |

||

|

Permitted Variations in Wall thickness (%) |

||

|

Tolerance, % from Nominal |

||

|

NPS Designator |

Over |

Under |

|

All |

Not specified |

-12.5 |

|

where: t=Nominal Wall Thickness D=Ordered Outside Diameter |

|

|

|

Outside Diameter |

Length(mm) |

|

|

Permitted Variations in Outside Diameter (mm) |

||

|

NB |

Tolerance |

Tolerance |

|

- 4 |

±0.79 |

+6 .4 / -0 mm |

|

5 - 8 |

+ 1.58 / -0.79 |

|

|

10-18 |

+ 2.37 / -0.79 |

|

|

20- 24 |

+3.18 / -0.79 |

|

|

ASME SA790 / ASTM A790 S31803 SS SMLS Pipe |

ASME SA928 / ASTM A928 S31803 SS Welded Pipe |

|

ASTM A790 S31803 Boiler Pipes Supplier |

SA928 / A928 S31803 Inox Tubes and pipes |

|

S31803 ASME SA 790 Seamless Steel Pipes Exporter |

SUS S31803 inox Steel Welded Tubing Stockist |

|

A789 S31803 Stainless Steel Pipes in Iraq |

2205 ASTM A928 Stainless Steel welded Mechanical Tubes |

|

ASTM A790 1.4462 S31803 Duplex Steel Pipe in Korea |

A928 S31803 welded Inox Steel Tube stockist |

|

ASTM A790 S31803 Hot Finished Seamless Steel Pipe in Germany |

A928 / SA928 Grade S31803 Stainless ERW Welded steel Tubes |

|

IBR Approved S31803 ASTM A790 stainless steel Tubes |

IBR Approved ASTM A928 S31803 Tubing Stockist |

|

ASTM A790 Duplex Steel Seamless Pipe in Peru |

ASTM A928 Steam Boiler Tubes Stockholder |

|

High Quality S31803 A790 Duplex steel Pipes in Malaysia |

2205 Duplex steel Tubes Manufacturer |