5.3.1 – Classes 20, 21, 22 and 23 pipe shall be uniformly heated within the post-weld heat-treatment temperature range indicated in the table below for a minimum of 1 hour per inch (0.4 hr/cm) of thickness or for 1 hour, whichever is greater.

5.3.2 – Classes 30, 31, 32 and 33 pipe shall be uniformly heated to a temperature in the austenitizing range and not exceeding the maximum normalizing temperature indicated in the table below and subsequently cooled in air at room temperature.

5.3.3 – Classes 40, 41, 42 and 43 pipe shall be normalized in accordance with 5.3.2. After normalizing, the pipe shall be reheated to the tempering temperature indicated in the table below as a minimum and held at temperature for a minimum of ½ hour per inch (0.2 hr/cm) of thickness or for ½ hour, whichever is greater, and air cooled.

5.3.4 – Classes 50, 51, 52 and 53 pipe shall be uniformly heated to a temperature in the austenitizing range not exceeding the maximum quenching temperature indicated in table below, and subsequently quenched in water or oil. After quenching, the pipe shall be reheated to the tempering temperature indicated in the table below as a minimum and held at that temperature for a minimum of ½ hour per inch (0.2 hr/cm) of thickness or for ½ hour, whichever is greater, and air cooled.

8.3 – Pressure Test – Classes X2 and X3 pipe shall be tested in accordance with specification A530/A530M, Hydrostatic Test Requirements.

9 – The full length of each weld of Classes X1 and X2 shall be radiographically examined in accordance with and meet the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Paragraph UW-51. Radiographic examination may be performed prior to heat treatment.

Scope

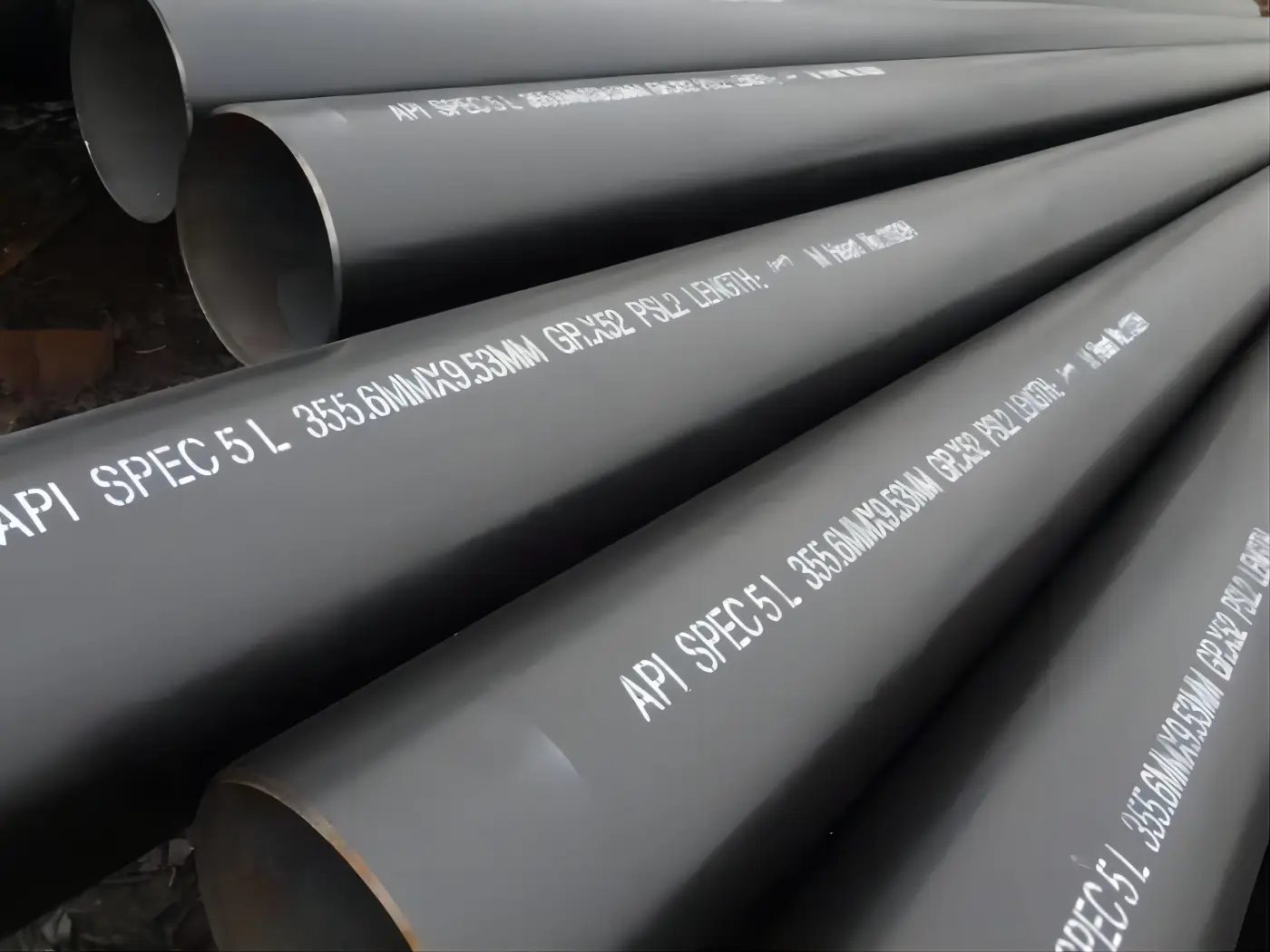

This specification covers electric fusion welded steel pipe with filler metal added, fabricated from pressure vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at atmospheric and lower temperatures. The specification nominally covers pipe 16 inches (400 mm) in outside diameter or larger and of ¼ inch (6 mm) wall thickness or greater. Pipe having other dimensions may be furnished provided it complies with all other requirements of this specification.

Chemical composition

Product analysis of plate: The pipe manufacturer shall make an analysis of each mill heat of plate material. The product analysis shall meet the requirements of the plate specification to which the material was ordered.

Product analysis of weld: The pipe manufacturer shall make an analysis of the finished deposited weld material from each 200 feet or fraction thereof. Analysis shall conform to the welding procedure for deposited weld metal.